Investment in the cold chain – specifically pre-cooling and transport refrigeration equipment – can reduce food loss by 76 percent and carbon dioxide equivalent emissions (CO2E) by 16 percent. These are the results of a pilot study on kinnow, a type of mandarin, commissioned by Carrier and released on December 9 at Carrier’s World Cold

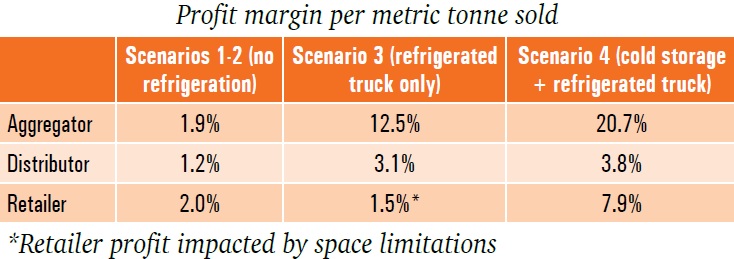

Chain Summit to Reduce Food Loss held in Singapore. Carrier is a part of UTC Climate, Controls & Security, a unit of United Technologies Corp. The pilot study examined the extent to which the cold chain can help increase the quality, reach and profitability of kinnow, a citrus fruit rich in micronutrients and common to the Punjab region of India and Pakistan, by enabling sales out-of-season and in distant markets. This is an area of critical importance to India, which is the world’s second largest producer of fruits and vegetables but accounts for just 1.5 percent of global produce exports due to losses of up to 20-50 percent of total production. The study was conducted by the Indian School of Business under the direction of the National Center for Cold-chain Development (NCCD) of India and Carrier Transicold India, and in collaboration with Balaji Kinnow, one of the largest aggregators in the Punjab region and the first to use a Carrier pre-cooling system, which is designed for the rapid removal of heat from freshly harvested produce. This process is typically done before the produce is shipped to market or put into cold storage. Demonstrating positive value for all stakeholders along the supply chain – growers, aggregators, transporters, distributors and retailers – the study corrects misperceptions that the cold chain requires a complex setup from farm to retail, dependence on other stakeholders to invest along the supply chain, and a high cost of investment. The study also provides a general framework for aggregators and distributors to analyze profitability for any crop when using the cold chain. Besides the economic value, the study also compared the carbon footprint of the kinnow supply chain with and without refrigeration, and determined that the cold chain can have a net decrease in overall carbon footprint when compared with the carbon emissions of kinnow that is lost or wasted. The study measured the effects of cold storage and refrigerated transport from Abohar in northern India to Bangalore in southern India, a roughly 2,500 km (1,600 mi) overland journey that is a four- to five-day drive by truck. This allowed for ample analysis of the time- and distance-related aspects of cold chain investment. Unlike other fruits, kinnow is available only for three to four months a year, is highly perishable and is grown primarily in a few districts of Punjab. To keep spoilage to a minimum, kinnow is best kept at 4- to 5-degrees Celsius and a relative humidity of 85- to 90-percent. Increasing yield and acreage has meant that production is too large for the local market, but there are challenges in distribution to markets that are further away. The study demonstrated that the payback for pre-cooling equipment is only about two years while for refrigerated trucks it is just over four years. Government incentives, which were not included in the study, would only further serve the attractiveness of the investment. Profitability was assessed comparing four monthly scenarios for the selling season, from January-March: two scenarios using open trucks (no refrigeration) for January (Scenario 1) and February (Scenario 2), and two scenarios using refrigerated trucks only in February (Scenario 3), and cold storage and refrigerated trucks in March (Scenario 4). In all scenarios, profitability improved for the aggregator, distributor and retailer, as follows:

Profit margin per metric tonne sold

| Scenarios 1-2 (no refrigeration) |

Scenario 3 (refrigerated truck only) |

Scenario 4 (cold storage + refrigerated truck) |

|

| Aggregator | 1.9% | 12.5% | 20.7% |

| Distributor | 1.2% | 3.1% | 3.8% |

| Retailer | 2.0% | 1.5% | 7.9% |

*Retailer profit impacted by space limitations

In addition, transporter profitability was 23 percent, based on two trips per month from Abohar to Bangalore using the income from the outbound journey with kinnow. As a result of the study, Balaji Kinnow has moved from renting to purchasing refrigerated truck units, along with investing a considerable amount in pre-cooling based on the preliminary results. The study also assessed the carbon footprint of supply chain activities and found that in comparison with greenhouse gas emissions from kinnow spoilage, cold chain intervention reduced overall CO2E emissions by 16 percent comparing February sales using an open truck (Scenario 2) with March sales using a refrigerated truck (Scenario 3). There was a 7.5 percent reduction in CO2E emissions between February (Scenario 2) and March (Scenario 4), allowing for the combined usage of cold storage and refrigerated truck. According to a 2015 study produced for the Global Food Cold Chain Council, the introduction of refrigerated technologies in emerging economies can reduce the net greenhouse gas impact of food waste by a factor of 10 to 1.

To review the full India pilot study, visit www.naturalleader.com

To learn more about reducing food waste, visit www.carrier.com

Disclaimer: The information provided within this publication / eBook/ content is for general informational purposes only. While we try to keep the information up-to-date and correct, there are no representations or warranties, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the information, products, services, or related graphics contained in this publication / eBook/ content for any purpose. Any use of this information is at your own risk.

Youth

Youth

Women

Women

Research for Ishrae

Research for Ishrae